ガスタンクの清掃は、特に古い車両や長期間使用されずに放置されている機器については、定期的なメンテナンスサイクルの一環として行うべきである。

給油所の運営、車両のメンテナンス、古い車両のレストアなど、どのような場合でも、適切なガソリンタンククリーナーを使用することは、安全性と性能のために非常に重要です。

時間が経つと、タンクには堆積物、錆、スラッジが蓄積し、燃料の品質を低下させ、エンジンを損傷させます。そこで、信頼性の高いガスタンク・クリーナーが活躍する。

燃料タンクから定期的にスラッジを除去することは、タンクの完全性を維持し、燃料の品質を向上させ、不必要なダウンタイムを防止する上で極めて重要である。

適切なタンク清掃は、燃料貯蔵や船舶から廃水や食品用容器に至るまで、さまざまな業界で不可欠です。時間の経過とともに、タンクにはスラッジや残留物、時には有毒ガスが溜まり、危険で非効率なものとなります。定期的な洗浄を行わないと、タンクは腐食、汚染、機械的故障の温床となります。タンク清掃を無視してはならない理由 多くのオペレータは、悪臭、燃料品質の低下、機器の損傷などの問題が表面化するまで、タンク清掃を遅らせる。しかし、定期的な清掃は確実である:このメンテナンスを怠ると、スラッジの堆積、微生物の繁殖、さらには燃料システムの詰まりにつながる可能性がある。タンク洗浄の方法 タンク洗浄には、タンクの内容物、サイズ、汚れのレベルに応じて、複数のアプローチがある:[...]

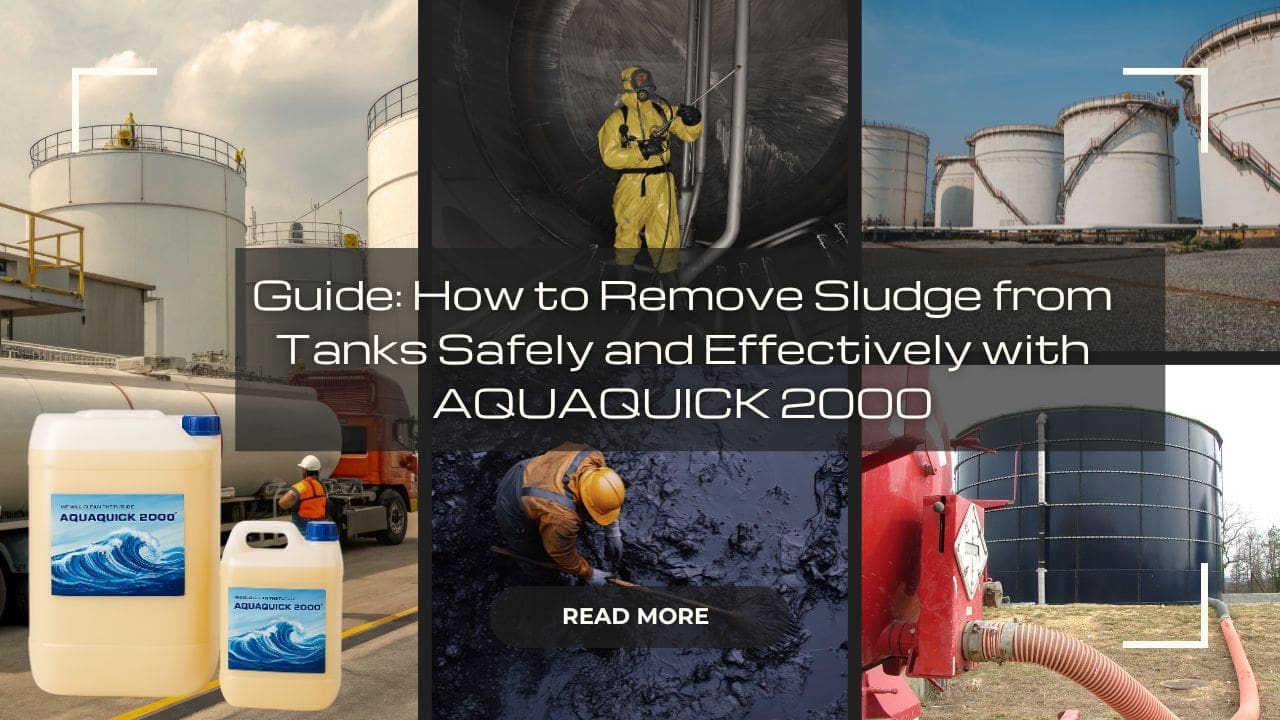

確かに!産業用タンクからスラッジを除去する場合、適切な洗浄方法と製品を使用することが重要です。スラッジの蓄積は、能力の低下、汚染、腐食、高価なダウンタイムにつながります。幸いなことに、石油、廃棄物、化学、製造の各分野の専門家から信頼されている信頼できるソリューションがあります:aquaquick 2000です。この記事では、アクアクイック2000を使用したタンク洗浄とスラッジ除去の実践的な手順をご案内し、この環境に優しい洗浄剤が現代の産業用途に理想的である理由をご説明します。スラッジ除去が産業用にとって重要な理由

工業用タンクの清掃は、石油、化学、廃棄物管理業界において、最も重要でありながら困難なメンテナンス作業のひとつです。燃料、炭化水素、グリース、工業副産物を貯蔵するタンクは、時間の経過とともにスラッジが厚く堆積し、操業上、環境上、安全上、深刻な問題を引き起こすことがよくあります。そのため、強力で安全、かつ環境に配慮した適切なタンク洗浄ソリューションの選択が不可欠です。AQUAQUICK 2000は、世界中のプロフェッショナルに愛用されているタンク洗浄剤です。オイルスラッジの除去、ケミカルタンクの脱脂、セパレーターピットの洗浄など、AQUAQUICK 2000は、コーティングの損傷や環境への悪影響、危険性を伴うことなく、安全で効果的なタンク洗浄を実現します。

タンク内のスラッジ堆積は、石油・ガス、海運、食品加工、廃水処理などの産業が直面する最も根強く、コストのかかる問題の一つです。固まった油かすであれ、付着したグリースであれ、炭化水素スラッジであれ、タンクからスラッジを効果的かつ安全に除去する必要性は、作業効率と安全性にとって極めて重要です。AQUAQUICK 2000は、過酷な化学薬品や安全でない方法を使用せずにスラッジ除去を簡素化する、専門的で無害な、コーティングに適した方法を提供します。スラッジを除去しなければならない理由 タンクスラッジを放置しておくと、次のようなことが起こります:スラッジの除去は、タンクメンテナンスの一環として日常的に行う必要があります。しかし、従来の方法(掻き取り、溶剤脱脂、酸洗浄など)は、設備にダメージを与え、作業員に害を及ぼし [...] [...]ます。

タンク内のスラッジ堆積は、石油や海運から食品加工や廃水管理まで、多くの産業にわたる普遍的な課題である。スラッジはタンクの容量を減らし、腐食を促進し、新しい製品を汚染し、検査を複雑にします。幸いなことに、スラッジの除去は、危険で、費用がかかり、環境にダメージを与えるものではありません。このガイドでは、無害でコーティングに適した洗浄剤であるアクアクイック2000を使用した、スラッジ除去のためのタンク洗浄の方法について説明します。タンクスラッジを理解する スラッジは通常、以下の混合物である:スラッジは、攪拌が最低限で熱の低い底部やタンク下部の壁面に堆積する傾向があります。時間の経過とともに固まり、粘着性または[...]汚泥になります。

石油・ガスから製造業まで、あらゆる業界の貯蔵タンクは、スラッジの堆積という共通の問題にさらされています。このタンク洗浄のデモンストレーションでは、AQUAQUICK 2000を手動洗浄と圧力アシスト洗浄の両方の方法で使用し、厚い炭化水素スラッジと油状残留物を安全かつ効果的に除去しました。その結果、本製品が現在業界で最も信頼できるタンク洗浄剤のひとつである理由が再確認されました。🎥 タンク洗浄のデモはこちら スラッジのシナリオ:こびりついた層と頑固な膜 このデモで紹介されたタンクは、床面と下部壁面に沿ってスラッジが堆積し、その他の内部表面は粘着性の油膜で覆われていました。このような状態は [...] 続きを読む