Konserwacja narzędzi i sprzętu ma zasadnicze znaczenie dla zapewnienia ich długoterminowej wydajności, bezpieczeństwa i niezawodności. Niniejszy artykuł zawiera szczegółowy przewodnik krok po kroku dotyczący czyszczenia narzędzi, niezależnie od tego, czy chodzi o narzędzia ręczne, elektronarzędzia czy sprzęt klasy przemysłowej. Wykonanie tych kroków pomoże wydłużyć żywotność narzędzi i utrzymać je w doskonałym stanie technicznym.

Znaczenie czyszczenia narzędzi

Regularne czyszczenie narzędzi to coś więcej niż tylko dbanie o ich nowy wygląd. Właściwa konserwacja pomaga zapobiegać zużyciu, minimalizuje ryzyko awarii i zapewnia bezpieczeństwo użytkowania. Brud, brud, rdza i nagromadzony olej mogą wpływać na działanie narzędzia, zmniejszać jego wydajność, a nawet prowadzić do przedwczesnej awarii. Utrzymywanie narzędzi w czystości nie tylko zwiększa produktywność, ale także chroni inwestycję w te cenne aktywa.

Narzędzia wymagające regularnego czyszczenia

Narzędzia ręczne

Narzędzia ręczne, takie jak klucze, szczypce i śrubokręty, mają tendencję do gromadzenia brudu, oleju i brudu w wyniku wielokrotnego użytkowania. Odpowiednie czyszczenie pomaga tym narzędziom działać płynnie i wydłuża ich żywotność.

Elektronarzędzia

Elektronarzędzia, w tym wiertarki, piły i szlifierki, są podatne na gromadzenie się pyłu, smaru i oleju, co może wpływać na ich wydajność i bezpieczeństwo. Czyszczenie tych narzędzi zapobiega ich przegrzaniu i utrzymuje je w dobrym stanie.

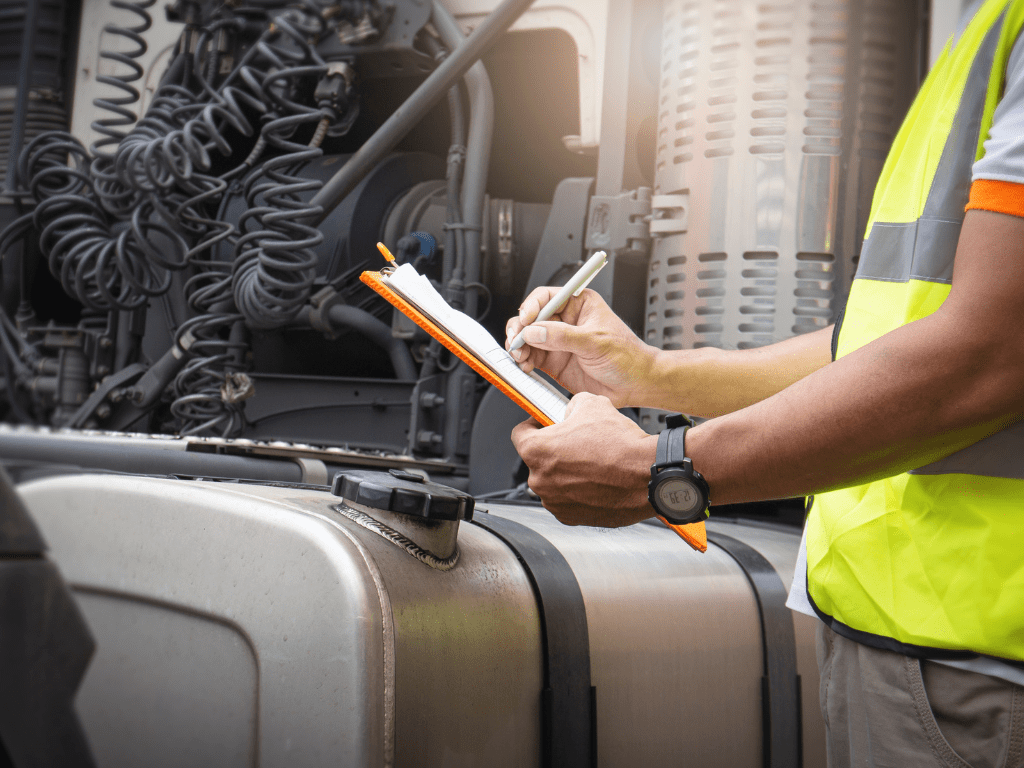

Narzędzia przemysłowe

Branże takie jak lotnictwo, wojsko, wydobycie ropy naftowej i produkcja opierają się na specjalistycznym sprzęcie, który wymaga rygorystycznej konserwacji. Narzędzia takie jak przewody wiertnicze, rury produkcyjne i narzędzia wiertnicze wymagają dokładnego czyszczenia, aby uniknąć zanieczyszczenia i zapewnić wysoką niezawodność.

Kroki do Czyszczenie narzędzi Skutecznie

1. Przygotowanie do czyszczenia wstępnego

Przed rozpoczęciem należy zebrać wszystkie niezbędne środki czyszczące. W zależności od poziomu zabrudzenia lub rdzy na narzędziach, możesz potrzebować odtłuszczacza, szczotki do czyszczenia, szmatki, wody i ewentualnie odrdzewiacza.

Uwaga dotycząca bezpieczeństwa: Należy nosić rękawice ochronne i, w razie potrzeby, okulary ochronne, aby uniknąć kontaktu z chemikaliami i zapobiec obrażeniom podczas procesu czyszczenia.

2. Usuwanie brudu i zanieczyszczeń

Dla narzędzi ręcznych:

- Użyj szczotki lub ściereczki aby zetrzeć luźny brud, kurz i zanieczyszczenia.

- W przypadku trudno dostępnych miejsc, stara szczoteczka do zębów może być skuteczna.

Dla elektronarzędzi:

- Odłącz narzędzie przed czyszczeniem.

- Użyj sprężonego powietrza, aby usunąć kurz z otworów wentylacyjnych silnika i skomplikowanych części.

3. Odtłuszczanie i głębokie czyszczenie

Po wstępnym czyszczeniu należy zastosować środek odtłuszczający, aby rozpuścić tłuszcz i uporczywy brud. W tym przypadku silnie skoncentrowany środek czyszczący, taki jak AQUAQUICK 2000 może być niezwykle przydatny. AQUAQUICK 2000 jest przeznaczony do skutecznego usuwania oleju, brudu i innych materiałów, które z czasem gromadzą się na narzędziach. Jego formuła jest silna, a jednocześnie wszechstronna, dzięki czemu nadaje się do ogólnego czyszczenia różnych typów sprzętu.

Używanie AQUAQUICK 2000 do odtłuszczania

- Zastosuj AQUAQUICK 2000 bezpośrednio na powierzchnię narzędzia, szczególnie na obszarach z olejem i uporczywym brudem.

- Pozostawić w spokoju przez kilka minut, aby spenetrować i poluzować brud.

- Użyj szczotki, aby delikatnie usunąć zanieczyszczenia.

Usuwanie rdzy z narzędzi metalowych

4. Sprawdzanie i usuwanie rdzy

Rdza może z czasem pogorszyć jakość i użyteczność metalowych narzędzi. Oto jak skutecznie radzić sobie z rdzą:

- Namoczyć narzędzie w odrdzewiaczu lub roztworze octu w przypadku łagodnej rdzy.

- W przypadku silnej rdzy należy wyszorować powierzchnię szczotką drucianą po zastosowaniu odrdzewiacza.

- Dokładnie opłucz narzędzie i całkowicie je wysusz, aby zapobiec rdzewieniu w przyszłości.

Końcowe czyszczenie i płukanie

Po odtłuszczeniu i usunięciu rdzy nadszedł czas, aby wypłukać narzędzia w celu usunięcia wszelkich pozostałości środków czyszczących. Ten krok jest szczególnie ważny, jeśli używałeś silnych odtłuszczaczy, takich jak AQUAQUICK 2000 aby uniknąć jakichkolwiek pozostałości.

5. Płukanie narzędzi

- Narzędzia ręczne: Spłukać czystą wodą i wytrzeć suchą szmatką.

- Elektronarzędzia: Tylko w przypadku części nieelektrycznych należy ostrożnie wytrzeć wszelkie pozostałości wilgotną szmatką.

Narzędzia do suszenia i smarowania

6. Proces suszenia

Dokładne wysuszenie narzędzi po czyszczeniu ma kluczowe znaczenie, ponieważ wilgoć pozostawiona na metalowych częściach może prowadzić do rdzy.

- Do wycierania narzędzi bezpośrednio po płukaniu należy używać suchego, czystego ręcznika.

- W razie potrzeby użyj niskiej temperatury suszarki do włosów, aby upewnić się, że cała wilgoć została odparowana z trudno dostępnych miejsc.

7. Smarowanie

Po wyczyszczeniu i wysuszeniu narzędzi, nałożenie lekkiej warstwy smaru może zapobiec powstawaniu rdzy i utrzymać narzędzia w dobrym stanie technicznym.

- Wybierz odpowiedni smar: W przypadku narzędzi ręcznych należy używać smaru na bazie oleju do części ruchomych.

- Stosować oszczędnie: Należy unikać nadmiernego smarowania, ponieważ nadmiar oleju może przyciągać brud.

Najlepsze praktyki w zakresie konserwacji narzędzi

Regularne czyszczenie narzędzi to skuteczny sposób na ich konserwację, ale jak je czyścić? Cóż, przyjęcie tych najlepszych praktyk dodatkowo pomoże przedłużyć ich żywotność i utrzymać ich wydajność.

Rutynowy harmonogram czyszczenia

- Narzędzia ręczne: Wycierać po każdym użyciu i czyścić co miesiąc.

- Elektronarzędzia: Czyścić po intensywnym użytkowaniu lub w razie potrzeby w zależności od środowiska pracy.

- Narzędzia przemysłowe: Zaplanuj regularne kontrole konserwacyjne i czyszczenie zgodnie z częstotliwością użytkowania.

Właściwe przechowywanie

Właściwe przechowywanie narzędzi może również zmniejszyć częstotliwość ich czyszczenia.

- Przechowywać w suchym miejscu: Wilgoć może prowadzić do powstawania rdzy, dlatego narzędzia należy przechowywać w środowisku wolnym od wilgoci.

- Używaj organizerów narzędzi: Zainwestuj w stojaki na narzędzia, skrzynki lub szafki, aby utrzymać narzędzia w porządku i chronić je.

Dodatkowe wskazówki dotyczące konserwacji narzędzi

Chociaż regularne czyszczenie jest niezbędne, istnieje kilka dodatkowych praktyk, które mogą pomóc w utrzymaniu narzędzi w jak najlepszym stanie.

Sprawdź narzędzia pod kątem uszkodzeń

Częste użytkowanie może powodować zużycie każdego narzędzia. Wyrób sobie nawyk sprawdzania narzędzi po każdym użyciu pod kątem oznak uszkodzeń, takich jak pęknięcia, tępe krawędzie lub luźne części.

- Wymiana uszkodzonych części: W przypadku elektronarzędzi należy jak najszybciej wymienić zużyte części, aby zapobiec dalszym problemom.

- Ostrzenie noży i bitów: Regularnie ostrzyć narzędzia tnące, aby utrzymać ich wydajność i zmniejszyć obciążenie narzędzia.

Prawidłowe korzystanie z narzędzi

Używanie narzędzia niezgodnie z jego przeznaczeniem może prowadzić do jego szybszej degradacji. Unikaj przeciążania elektronarzędzi i zawsze używaj odpowiedniego rozmiaru i typu narzędzia do każdego zadania, aby zminimalizować zużycie.

Dogłębne czyszczenie urządzeń przemysłowych

Branże takie jak lotnictwo, wydobycie ropy naftowej i produkcja polegają na specjalistycznym sprzęcie, w którym skuteczne czyszczenie i odtłuszczanie ma kluczowe znaczenie dla zapobiegania zanieczyszczeniom i utrzymania wydajności. Produkty takie jak AQUAQUICK 2000 są wysoce zalecane do tych zastosowań ze względu na ich silną, skoncentrowaną formułę. AQUAQUICK 2000 jest idealny do zastosowań takich jak czyszczenie przewody wiertnicze, przewody produkcyjne, elektroniczne elementy sterujące i narzędzia wiertnicze używane w trudnych warunkach.

AQUAQUICK 2000 dla urządzeń przemysłowych

AQUAQUICK 2000 został specjalnie opracowany do rozpuszczania trudnych osadów, z którymi konwencjonalne środki czyszczące mogą mieć trudności. Jego zdolność do szybkiego usuwania olejów, brudu i wypełniaczy sprawia, że jest cenny dla precyzyjnych narzędzi i sprzętu. Dzięki zastosowaniu tego innowacyjnego rozwiązania, branże mogą osiągnąć wysokiej jakości rezultaty czyszczenia bez konieczności stosowania środków ściernych lub szkodliwych chemikaliów.

Jak używać AQUAQUICK 2000 Do różnych zastosowań czyszczących

Czyszczenie ogólne

Do ogólnego czyszczenia narzędzi ręcznych i elektronarzędzi, AQUAQUICK 2000 może być stosowany w postaci rozcieńczonego roztworu. Dzięki temu jest ekonomiczny, a jednocześnie zapewnia silne działanie odtłuszczające.

Odtłuszczanie przy dużych obciążeniach

W przypadku ciężkich zastosowań przemysłowych należy zastosować AQUAQUICK 2000 w zalecanym pełnym stężeniu, aby usunąć trudne zabrudzenia, olej i pozostałości. Proces ten jest bardzo skuteczny w przypadku narzędzi i maszyn narażonych na działanie oleju lub pracujących w szczególnie wymagających środowiskach, takich jak pola naftowe lub warsztaty maszynowe.

Procedura czyszczenia:

- Zastosuj AQUAQUICK 2000 na dotknięty obszar i pozostawić na kilka minut.

- Użyj szczotka lub gąbka delikatnie, ale dokładnie wyszorować powierzchnię.

- Spłukać wodą i całkowicie wysuszyć, a w razie potrzeby nasmarować.

Względy środowiskowe

AQUAQUICK 2000 jest przeznaczony do przyjazny dla środowiskadzięki czemu jest to bezpieczniejsza opcja zarówno dla użytkowników, jak i środowiska. Ponieważ branże coraz bardziej zwracają uwagę na wpływ na środowisko, wybór biodegradowalnego środka czyszczącego, takiego jak AQUAQUICK 2000, pomaga zmniejszyć ilość odpadów chemicznych i zminimalizować szkodliwe emisje.

Wskazówki dotyczące utylizacji i bezpieczeństwa

- Odpowiedzialne usuwanie zużytych środków czyszczących, przestrzegając wszelkich lokalnych przepisów dotyczących utylizacji chemikaliów.

- Używanie sprzętu ochronnego takich jak rękawice i ochrona oczu podczas pracy ze skoncentrowanymi środkami czyszczącymi.

- Wentylacja przestrzeni roboczej podczas stosowania w zamkniętych pomieszczeniach, aby uniknąć wdychania oparów.

Korzyści z używania AQUAQUICK 2000 do czyszczenia narzędzi

Podsumowując, AQUAQUICK 2000 oferuje wiele zalet, które sprawiają, że jest to preferowane rozwiązanie do czyszczenia i odtłuszczania narzędzi:

- Potężna koncentracja: Jego wysoce skoncentrowana formuła skutecznie usuwa brud i olej, nawet z trudno dostępnych miejsc.

- Wszechstronność: Nadaje się do różnych narzędzi, w tym narzędzi ręcznych, elektronarzędzi i sprzętu przemysłowego.

- Przyjazny dla środowiska: Ulega biodegradacji, zmniejszając szkodliwy wpływ na środowisko.

- Opłacalność: Ponieważ AQUAQUICK 2000 może być rozcieńczany do ogólnego czyszczenia, oferuje elastyczność dla różnych intensywności czyszczenia.

Często zadawane pytania

P: Jak często należy czyścić narzędzia?

O: Regularnie czyść narzędzia ręczne co miesiąc, elektronarzędzia po każdym istotnym użyciu, a narzędzia przemysłowe w zależności od zastosowania i środowiska.

P: Czy mogę używać AQUAQUICK 2000 na delikatnych powierzchniach?

O: Tak, AQUAQUICK 2000 jest uniwersalny i bezpieczny dla delikatnych części, jeśli jest używany zgodnie z zaleceniami. Przed użyciem należy zawsze sprawdzić kompatybilność.

P: Jak mogę zapobiec rdzewieniu moich narzędzi?

O: Po wyczyszczeniu narzędzia należy dokładnie osuszyć, nałożyć lekką warstwę smaru i przechowywać w suchym miejscu o kontrolowanej temperaturze.

Wnioski

Czyszczenie narzędzi jest istotną częścią konserwacji, która nie tylko zwiększa ich wydajność, ale także wydłuża ich żywotność. Stosowanie skutecznych rozwiązań czyszczących, takich jak AQUAQUICK 2000zapewnia dokładne odtłuszczanie i usuwanie zanieczyszczeń bez szkody dla narzędzi i środowiska. Postępując zgodnie z tymi krokami, możesz utrzymać swoje narzędzia w doskonałym stanie i gotowości do niezawodnej pracy, zarówno do użytku osobistego, jak i wymagających zastosowań przemysłowych.

Dzięki regularnej pielęgnacji, właściwemu przechowywaniu i stosowaniu odpowiednich produktów, narzędzia pozostaną cennymi, niezawodnymi zasobami przez wiele lat.