Sludge buildup inside tanks is a universal challenge across many industries — from petroleum and shipping to food processing and wastewater management. Sludge reduces tank capacity, accelerates corrosion, contaminates new product, and complicates inspections. Fortunately, sludge removal doesn’t have to be hazardous, expensive, or environmentally damaging. In this guide, we’ll explain how to approach tank cleaning for sludge removal using AQUAQUICK 2000 — a non-toxic, coating-friendly cleaning agent that simplifies the entire process. Understanding Tank Sludge Sludge is typically a mix of: Sludge tends to accumulate at the bottom and along lower tank walls, where agitation is minimal and heat is low. Over time, it hardens and becomes sticky or […]

Storage tanks across industries — from oil & gas to manufacturing — are vulnerable to one common problem: sludge buildup. In this tank cleaning demonstration, AQUAQUICK 2000 was used in both manual and pressure-assisted cleaning methods to remove thick hydrocarbon sludge and oily residue safely and effectively. The results reaffirm why this product is one of the most reliable tank cleaning agents in the industry today. 🎥 Watch the tank cleaning demo here The Sludge Scenario: Caked Layers and Stubborn Films The tank shown in this demonstration featured sludge buildup along the floor and lower walls, with sticky oil films coating the rest of the internal surfaces. These conditions are […]

Sludge is the silent enemy of industrial storage tanks. Over time, hydrocarbons, sediments, and residues accumulate into thick, immobile sludge that compromises tank capacity, quality control, and safety. In this tank cleaning demonstration, AQUAQUICK 2000 was deployed to show exactly how it can break down heavy sludge deposits using simple, safe, and efficient cleaning practices. Whether you’re dealing with oil tanks, chemical storage units, or grease-contaminated containers, this demonstration proves why AQUAQUICK 2000 is one of the most effective tank cleaning agents on the market. The Demo Setup: Real Tanks, Real Sludge The tanks featured in the demo video were moderately filled with sludge-heavy hydrocarbon waste, layered with oily residue […]

Sludge accumulation in petroleum storage tanks is one of the most stubborn and costly maintenance issues industrial operators face. In the PDB tank cleaning project, the use of AQUAQUICK 2000 as a tank cleaning agent proved to be a game-changer. The cleaning team successfully removed thick, settled sludge without damaging the tank’s interior or requiring hazardous manual scraping. This article outlines how AQUAQUICK 2000 was applied, why it worked so effectively, and what best practices to follow when dealing with similar sludge-heavy tanks. The Sludge Scenario: Why It Was a Challenge Petroleum sludge typically forms a dense, sticky layer at the bottom of storage tanks due to the separation of […]

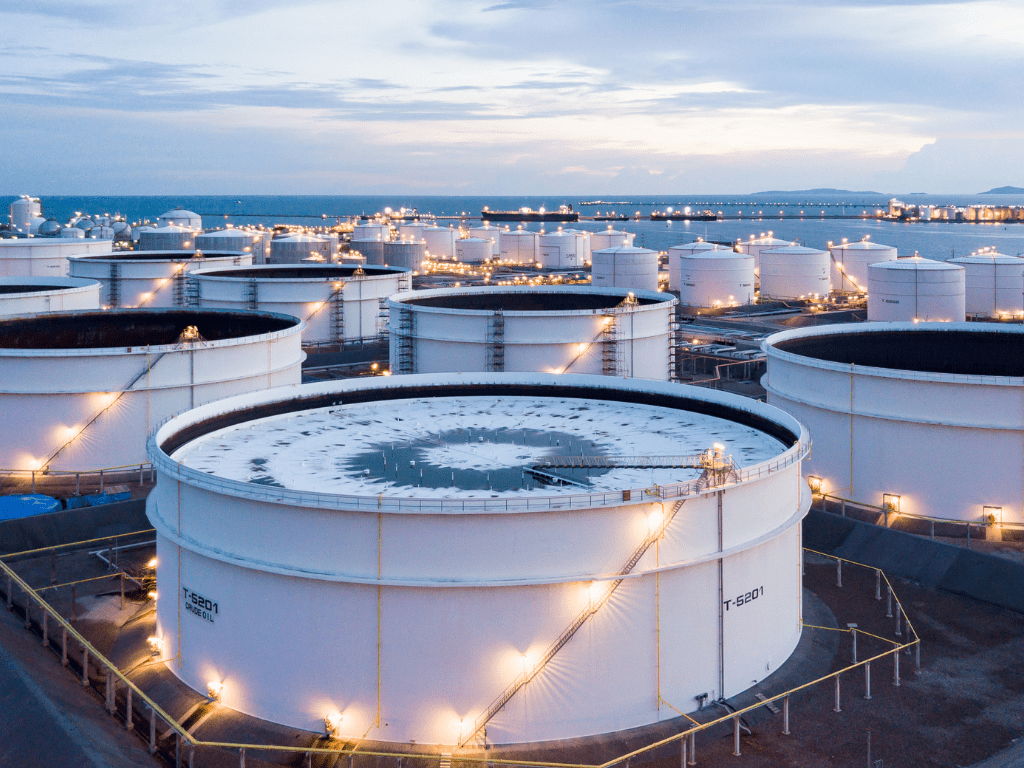

Tank cleaning in oil fields often involves the removal of highly viscous, compacted sludge that has settled over months or years. In this second PDO Oman tank cleaning case, AQUAQUICK 2000 was once again proven to be the ideal tank cleaning agent, handling thick sludge with ease, without endangering tank linings, coatings, or worker safety. The project reinforces the consistent performance of AQUAQUICK 2000 across multiple real-world industrial scenarios. The Sludge Problem: Heavy, Sticky Residue This particular storage tank in Oman had accumulated a tough, layered sludge—common in hydrocarbon tanks where oil residues settle and thicken over time. Manual removal would have posed safety risks and consumed significant labor hours. […]

Heavy sludge buildup in oil storage tanks is a persistent and costly challenge, especially in the energy sector. At the Petroleum Development Oman (PDO) site, AQUAQUICK 2000 was deployed as the primary tank cleaning agent to safely and effectively remove dense hydrocarbon sludge during a major tank maintenance operation. This project showcased how AQUAQUICK 2000 excels as a tank cleaning solution in high-demand environments—without the risks associated with harsh solvents or abrasive methods. The Challenge: Thick, Settled Sludge The storage tank in question had accumulated layers of sticky, compact sludge over time—typical of long-term oil residue settling. Such conditions make manual entry dangerous and slow, while traditional chemical degreasers often […]

Tank cleaning is one of the most essential yet challenging maintenance operations in industrial environments. When storage tanks accumulate sludge, hydrocarbon residues, or chemical deposits, choosing the right tank cleaning agent and method becomes critical to ensure safety, efficiency, and protection of the tank’s internal coating. AQUAQUICK 2000 stands out as a trusted tank cleaning solution—especially when paired with high pressure jet systems. Why Use High Pressure Jetting for Tank Cleaning? High pressure jetting is a widely adopted method for tank cleaning, particularly effective when dealing with heavy sludge or stubborn hydrocarbon residues. It uses water pressure (commonly up to 3500 PSI) to dislodge and remove the contaminants from the […]

Over time, sludge, residues, and contaminants accumulate inside the tank. That’s why cleaning fuel tank thoroughly and regularly should be a top priority.

we will explore effective strategies for preventing oil spills in industrial operations and the role of products like Aquaquick 2000 in mitigating the risks associated with oil spill incidents.

When it comes to maintaining fuel, chemical, or wastewater tanks, safety isn’t just a priority—it’s a necessity. Safety tank cleaning ensures not only that the tank is free from hazardous sludge, gases, and residues, but also that the workers involved remain protected during the process. Whether it’s an underground fuel tank or a large industrial storage tank, following proper procedures is critical. Understanding the Importance of Safety Tank Cleaning Over time, tanks accumulate: Ignoring proper safety tank cleaning procedures can lead to explosions, environmental contamination, and severe health hazards for maintenance staff. Key Safety Measures for Tank Cleaning To ensure effective safety tank cleaning, implement these critical practices: 1. Pre-Cleaning […]