Sludge is the silent enemy of industrial storage tanks. Over time, hydrocarbons, sediments, and residues accumulate into thick, immobile sludge that compromises tank capacity, quality control, and safety. In this очистка резервуаров demonstration, AQUAQUICK 2000 was deployed to show exactly how it can break down heavy sludge deposits using simple, safe, and efficient cleaning practices. Whether you’re dealing with oil tanks, chemical storage units, or grease-contaminated containers, this demonstration proves why AQUAQUICK 2000 is one of the most effective tank cleaning agents on the market.

The Demo Setup: Real Tanks, Real Sludge

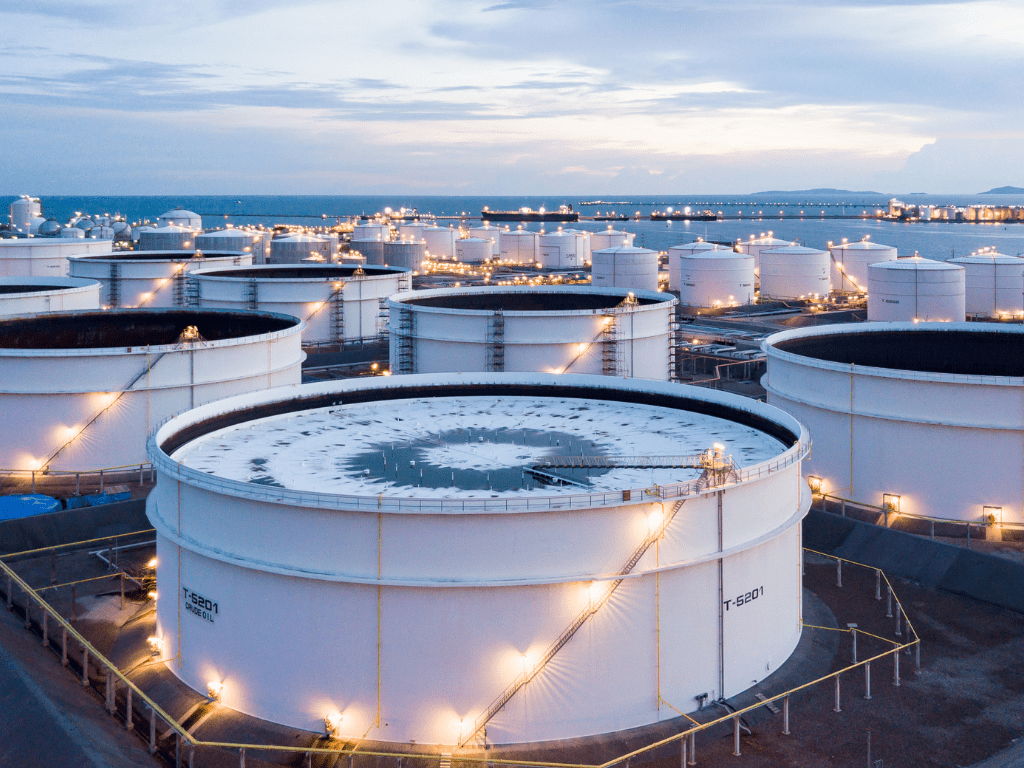

The tanks featured in the demo video were moderately filled with sludge-heavy hydrocarbon waste, layered with oily residue and caked-on sediment. These tanks represented typical conditions found in refineries, shipping yards, and fuel terminals. The goal was to clean them without damaging the interior lining or exposing workers to hazardous solvents.

🎥 Watch the Tank Cleaning Demo here

How AQUAQUICK 2000 Was Applied

- Pre-Clean Inspection:

- Teams assessed the sludge layer to determine the right dilution and cleaning system.

- Sludge was noted as semi-solid and sticky — ideal for emulsification.

- Dilution and Spray-In:

- AQUAQUICK 2000 was diluted at 1:20 and sprayed into the tank using a static nozzle system.

- A soak time of 15–25 minutes allowed the product to seep into the sludge and begin its chemical reaction.

- Heated Pressure Rinse:

- Tanks were rinsed using hot water (around 70°C) with 3000 PSI jets.

- The combination of heat, pressure, and AQUAQUICK 2000’s emulsifying power lifted the sludge and dislodged it from the walls and bottom of the tank.

- Final Pass and Manual Edge Cleaning:

- After the main sludge was flushed out, a team entered with safety equipment to manually wipe hard-to-reach areas using soft brushes and direct product application.

- No signs of corrosion, discoloration, or coating damage were observed.

The Science Behind Sludge Removal

AQUAQUICK 2000 works by breaking the surface tension between sludge and the tank surface. Once diluted and activated with heat, it penetrates hydrocarbon masses and separates them from metal or coated surfaces. The end result is a flowable emulsion that can be easily pumped out or flushed without needing scraping or hazardous solvents.

Peanut Butter Analogy:

Thick tank sludge is like a jar of peanut butter—too thick to pour, too stubborn to clean. AQUAQUICK 2000 acts like warm milk: it softens the mass into a pourable, flushable state. This analogy helps operators understand the emulsification power of AQUAQUICK 2000 in practical terms.

Cleaning Tips from the Demo

- Use internal tank heating if external water heating is limited to ensure sludge is soft enough to emulsify.

- Spray evenly across all surfaces, including weld seams and under internal structures.

- Let it soak, especially for sludge over 2 cm thick—don’t rush the breakdown process.

- Use brushes only for final polish, not for sludge removal. AQUAQUICK does the heavy lifting.

Why This Demo Matters

This demo clearly illustrates that tank cleaning for sludge removal can be safe, fast, and non-destructive. With no toxic fumes, no damaged linings, and no long downtime, AQUAQUICK 2000 proves itself as a next-generation tank cleaning solution for industries that demand performance without risk.