I. Introduction to Grease Trap Cleaning Guide

Grease traps play a crucial role in maintaining cleanliness and functionality within commercial kitchens and food service establishments. The accumulation of fats, oils, and grease (FOG) in these traps can lead to clogs, foul odors, and potential environmental hazards if not properly managed. Therefore, understanding the importance of regular grease trap cleaning in this guide is paramount for the smooth operation of any kitchen.

Importance of maintaining a clean grease trap:

A clean grease trap ensures the proper flow of wastewater by effectively trapping FOG and solid debris. This prevents clogs in drainage systems, reduces the risk of sewer backups, and helps maintain compliance with environmental regulations. Moreover, regular cleaning prolongs the lifespan of grease traps and reduces the need for costly repairs or replacements.

Overview of the process:

This grease trap cleaning guide involves several steps, including pre-cleaning preparation, the cleaning process itself, and post-cleaning maintenance. Proper safety precautions must be taken to protect workers from exposure to hazardous substances, and appropriate tools and equipment should be used to ensure thorough cleaning. Additionally, environmentally-friendly cleaning solutions should be prioritized to minimize negative impacts on the environment.

II. Understanding Grease Traps

Definition and purpose of a grease trap:

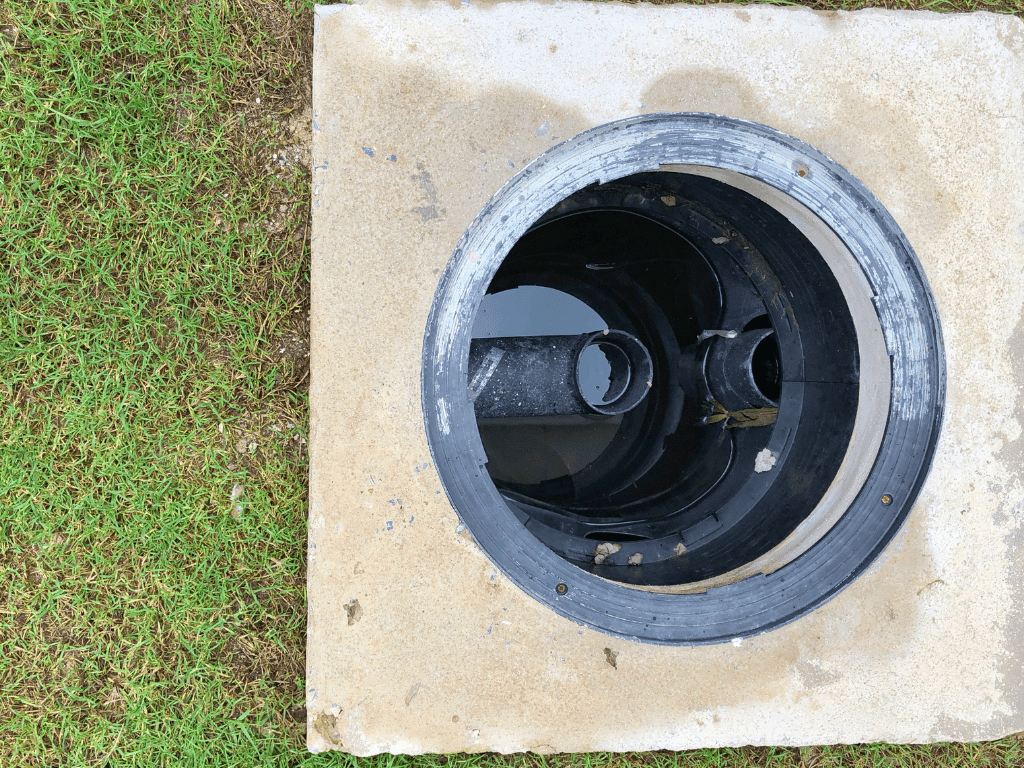

A grease trap, also known as a grease interceptor or grease separator, is a plumbing device designed to intercept FOG and solid waste from wastewater before it enters the sewer system. This prevents FOG from accumulating in sewer lines and causing blockages or overflows. Grease traps typically consist of a tank-like structure with baffles that slow down the flow of water, allowing FOG to separate and rise to the surface for containment.

Different types of grease traps:

Grease traps come in various designs, including passive hydromechanical, automatic, and gravity grease traps. Each type has its own unique mechanism for trapping FOG and solid waste, with different capacities and efficiency levels. Choosing the right type of grease trap depends on factors such as kitchen size, wastewater volume, and local regulations.

Grease trap size considerations:

The size of a grease trap is determined by factors such as the flow rate of wastewater, the amount of FOG generated, and the frequency of cleaning required. Proper sizing ensures that the grease trap can effectively capture and contain FOG without causing backups or overflows. Regular maintenance and inspection are essential to ensure that the grease trap remains adequately sized for the needs of the establishment.

III. How Grease Traps Work

Explanation of how grease traps capture fats, oils, and grease (FOG):

When wastewater containing FOG enters the grease trap, the flow is slowed down, allowing FOG to float to the surface while solid particles settle at the bottom. Baffles inside the trap help to trap and contain the FOG, preventing it from entering the sewer system. Over time, the accumulated FOG forms a layer that must be removed through regular cleaning to maintain the trap’s effectiveness.

Importance of regular cleaning for efficient operation:

Regular cleaning is essential to prevent FOG buildup, which can lead to clogs, foul odors, and reduced efficiency of the grease trap. Neglecting regular maintenance can result in costly repairs, environmental violations, and disruptions to kitchen operations. By adhering to a schedule of routine cleaning and maintenance, establishments can ensure the proper functioning of their grease traps and avoid potential problems down the line.

IV. Common Issues with Grease Traps

Understanding common issues with grease traps is a fundamental aspect of any Grease Trap Cleaning Guide. Grease traps are essential components of commercial kitchens, but they can experience various issues if not properly maintained. Understanding these common problems is crucial for timely intervention and prevention of potential hazards.

Signs of a full or malfunctioning grease trap:

- Slow drainage: One of the first indicators of a full grease trap is slow drainage in sinks, dishwashers, or floor drains.

- Foul odors: Accumulated FOG and solid waste can emit unpleasant odors, indicating that the grease trap requires cleaning.

- Grease overflow: If grease begins to overflow from the grease trap or back up into sinks or drains, it’s a clear sign of excessive buildup.

- Increased pest activity: Insects or rodents may be attracted to the buildup of organic matter in a neglected grease trap, leading to pest infestations.

- Structural damage: Over time, grease traps can deteriorate due to corrosion or damage, leading to leaks or cracks that compromise their effectiveness.

Potential hazards of neglecting grease trap maintenance:

- Environmental pollution: Untreated FOG can contaminate waterways and harm aquatic ecosystems, leading to environmental violations and fines.

- Health risks: Accumulated grease can harbor bacteria, pathogens, and foul odors, posing health hazards to kitchen staff and patrons.

- Plumbing problems: Clogged grease traps can cause backups and overflows in sewer lines, resulting in costly repairs and disruptions to kitchen operations.

- Fire hazards: Grease buildup in exhaust hoods and ductwork increases the risk of kitchen fires, endangering the safety of personnel and property.

V. Preparing for Grease Trap Cleaning

Before embarking on the grease trap cleaning process, it’s essential to take appropriate safety measures, gather necessary tools and equipment, and consider environmental implications.

Safety precautions:

- Wear protective gear, including gloves, goggles, and aprons, to minimize exposure to hazardous substances and prevent injury.

- Ensure proper ventilation in the kitchen area to dissipate fumes and odors generated during cleaning.

- Use caution when working with cleaning chemicals to avoid skin contact, inhalation, or accidental ingestion.

- Follow established protocols for handling and disposing of waste materials in compliance with local regulations.

Necessary tools and equipment:

- Grease trap cleaning tools: Including scrapers, brushes, and suction pumps for removing solid waste and FOG buildup.

- Cleaning solutions: Choose environmentally-friendly degreasers and detergents specifically formulated for grease trap cleaning.

- Protective equipment: Such as buckets, mops, and absorbent materials for containing spills and preventing contamination.

- Inspection tools: Flashlights, mirrors, and leak detectors for assessing the condition of the grease trap and identifying potential issues.

Environmental considerations:

- Minimize water usage during the cleaning process to conserve resources and reduce the volume of wastewater generated.

- Use biodegradable cleaning products to minimize environmental impact and comply with sustainability standards.

- Dispose of waste materials, including FOG, solid debris, and cleaning chemicals, in accordance with local regulations and guidelines.

- Implement best practices for spill prevention and containment to prevent accidental releases of hazardous substances into the environment.

VI. Step-by-Step Guide to Cleaning Your Grease Trap

This Grease Trap Cleaning Guide involves several steps to ensure thorough removal of FOG and solid waste, as well as routine maintenance to prevent future issues.

A. Pre-Cleaning Preparation

- Shutting off water supply: Turn off water flow to sinks and drains connected to the grease trap to prevent additional wastewater from entering during cleaning.

- Draining excess water from the trap: Use a suction pump or drain valve to remove standing water from the grease trap, facilitating easier access for cleaning.

- Removing accumulated debris: Use a scraper or brush to dislodge and remove solid waste, food particles, and grease buildup from the trap’s interior surfaces.

B. Cleaning Process

- Using appropriate cleaning solutions: Apply eco-friendly degreasers or enzymatic cleaners to dissolve and emulsify FOG, making it easier to remove.

- Scrubbing and removing grease buildup: Use brushes or scrubbing pads to agitate the cleaning solution and dislodge stubborn grease deposits from the trap’s walls and baffles.

- Rinsing thoroughly: Flush the grease trap with hot water to rinse away dissolved grease and cleaning residue, ensuring a clean and odor-free interior.

C. Post-Cleaning Maintenance

- Inspecting for leaks or damage: Thoroughly examine the grease trap for signs of leaks, cracks, or structural damage that may compromise its integrity.

- Reassembling the trap: Replace any removed components, such as baffles or gaskets, and ensure proper alignment and sealing to prevent leaks.

- Proper disposal of waste: Dispose of extracted FOG, solid waste, and cleaning residues in designated containers or disposal facilities in accordance with local regulations.

By following these steps and precautions, you can effectively clean your grease trap, mitigate potential hazards, and ensure the continued functionality of your kitchen’s wastewater management system.

VII. Oil Spill Management in Grease Traps

Grease traps are susceptible to oil spills due to the accumulation of fats, oils, and grease (FOG) from kitchen wastewater. Understanding the risks associated with oil spills in grease traps is essential for implementing preventive measures and effective cleanup procedures.

Understanding the risk of oil spills:

- Potential environmental impact: Oil spills from grease traps can contaminate waterways, soil, and wildlife, leading to ecological damage and regulatory violations.

- Health and safety hazards: Spilled oil can create slippery surfaces, increasing the risk of slips, falls, and injuries in kitchen environments.

- Structural damage: Overflows or leaks from grease traps can cause damage to plumbing systems, flooring, and surrounding infrastructure if not promptly addressed.

Implementing preventive measures:

- Regular maintenance: Schedule routine inspections and cleanings to prevent FOG buildup and reduce the risk of oil spills.

- Installation of spill containment devices: Implement secondary containment systems, such as spill trays or drip pans, to capture spills and prevent them from spreading.

- Employee training: Educate kitchen staff on proper grease trap maintenance procedures, spill response protocols, and the importance of spill prevention.

Steps for cleaning up oil spills in grease traps:

- Containment: Immediately contain the spill using absorbent materials, such as spill pads or absorbent socks, to prevent further spreading.

- Absorption: Use absorbent materials to soak up the spilled oil, ensuring thorough coverage of the affected area.

- Disposal: Dispose of saturated absorbents in accordance with local regulations, avoiding improper disposal methods that could harm the environment.

- Cleanup: Clean the spill area using eco-friendly degreasers and detergents to remove any remaining oil residue and restore cleanliness.

Utilizing oil spill dispersants and solutions:

Oil spill dispersants and solutions can aid in breaking down and emulsifying spilled oil, facilitating easier cleanup and minimizing environmental impact. AquaQuick 2000 is a highly effective oil spill dispersant that can be used in grease trap cleaning to enhance the breakdown of FOG and solid waste.

Introduction to AquaQuick 2000:

AquaQuick 2000 is a revolutionary cleaning solution specifically formulated for grease trap maintenance. Its advanced formula penetrates and disperses FOG, allowing for easier removal and preventing buildup within grease traps.

Benefits of using AquaQuick 2000 in grease trap cleaning:

- Enhanced cleaning power: AquaQuick 2000 effectively breaks down and emulsifies FOG, reducing the need for manual scrubbing and scraping during grease trap cleaning.

- Time and cost savings: Using AquaQuick 2000 can streamline the cleaning process, saving time and labor costs associated with traditional cleaning methods.

- Environmental compatibility: AquaQuick 2000 is biodegradable and environmentally friendly, minimizing its impact on ecosystems and water quality.

How AquaQuick 2000 helps in breaking down oil and waste in grease traps:

AquaQuick 2000 contains specialized surfactants and enzymes that target and degrade FOG molecules, breaking them down into smaller particles that can be easily flushed away.

Testimonials and case studies from various outlets where AquaQuick 2000 was used for grease trap maintenance:

Numerous establishments, including restaurants, fast-food chains, and commercial kitchens, have reported significant improvements in grease trap performance and cleanliness after incorporating AquaQuick 2000 into their cleaning routines. Testimonials and case studies provide real-world evidence of AquaQuick 2000’s effectiveness in grease trap maintenance.

Integrating AquaQuick 2000 into grease trap cleaning routine for enhanced effectiveness:

To maximize the benefits of AquaQuick 2000, it should be incorporated into a comprehensive grease trap cleaning and maintenance regimen. Regular use of AquaQuick 2000 can prevent FOG buildup, reduce the frequency of cleanings, and prolong the lifespan of grease traps, resulting in cost savings and improved efficiency.

VIII. FAQs – Grease Trap Cleaning Guide

How often should I clean my grease trap?

The frequency of grease trap cleaning depends on factors such as kitchen size, wastewater volume, and local regulations. However, as a general guideline, grease traps should be cleaned at least every 1-3 months to prevent FOG buildup and maintain optimal performance.

What are the consequences of not cleaning a grease trap regularly?

Neglecting regular grease trap cleaning can lead to clogs, backups, foul odors, and potential environmental violations. In severe cases, untreated FOG can cause structural damage to plumbing systems and result in costly repairs or replacements.

Can I use household cleaners to clean my grease trap?

Household cleaners are generally not recommended for grease trap cleaning, as they may not effectively break down FOG and can contain harmful chemicals that harm the environment. It is best to use specialized grease trap cleaners, such as AquaQuick 2000, that are specifically formulated for this purpose.

Are there any eco-friendly options for grease trap cleaning?

Yes, there are several eco-friendly options for grease trap cleaning, including biodegradable degreasers, enzymatic cleaners, and oil spill dispersants like AquaQuick 2000. These products are safer for the environment and provide effective cleaning without compromising performance.

IX. Conclusion

Regular maintenance and proper cleaning of grease traps are essential for ensuring the efficient operation of commercial kitchens and food service establishments. By understanding the risks of oil spills, implementing preventive measures, and utilizing innovative solutions like AquaQuick 2000, establishments can effectively manage grease trap maintenance and minimize environmental impact. With a commitment to regular cleaning and the use of eco-friendly products, establishments can ensure the longevity and reliability of their grease traps while promoting sustainability and compliance with regulatory standards.